Client type: Armoured vehicle retrofit

One customer was bidding on a job for refitting armoured vehicles.

The problem was proving that they could do the work. The firm was an excellent provider of armouring limousines, executive sedans and cash cars but full-sized armoured trucks was a different scale of problem.

All up armoured limousines need to do is get out of the ambush point. On the other hand, armoured trucks are not typically faced with destruction because the bad guys want what is inside.

What to do

How could this firm prove they were the ones who had the skill to upgrade all of the James Bond technologies inside of a modern armoured truck? They were given a demo vehicle to work on. The firm had welders, electricians, engineers with their own patents, sheets and sheets of ballistic steel, and even upholsterers who could refinish the interior.

That wasn’t the problem.

The problem was could they prove they could reproduce the process on dozens of vehicles in different facilities.

The solution

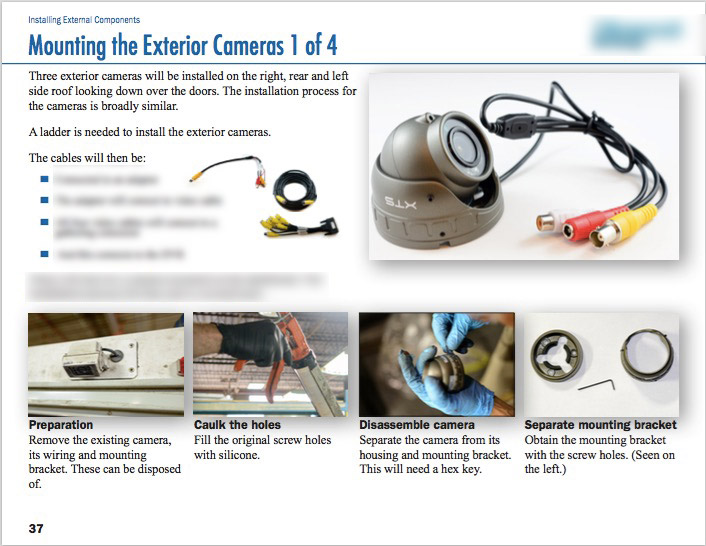

I wrote a book, an upgrade guide.

And what an upgrade guide it was. Of the three thousand, six hundred photos taken, four hundred made it in, along with a dozen blueprints, plus wiring schematics and parts lists. I photographed each step in disassembly, installation and reassembly.

The impact

With this book showing every step to be performed by the welders, electricians and engineers, the decision makers saw every step in the process, and could be confident that it could be replicated.