Client type: Manufacturing

After four years of business this successful manufacturer was still in start up mode. It was attempting to transition from small business to small enterprise. Despite spectacular year over year growth they remained in a cycle of fire fighting.

Orders doubled every year, equipment was being upgraded and developers working continually to upgrade the software, but somehow critical problems never seemed to go away

What to do

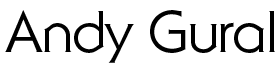

The first step was to document every process. The customer support team’s tasks were documented and presented as flowcharts.

The Solution

This easy to understand manual served several functions.

- It made it easy to train telephone support staff.

- It made it easy to hire staff — you could literally show them what they would be doing and give them a book to study before their first day at work.

- Performance reviews could be standardized.

- The process was repeated for the production department. This way anyone could step in and be trained easily.

The next critical task was to engage a part time HR specialist. Bringing in some grey hair to the company for a few hours a week helped the founders.

The Impact

The founding partners began to firefight less. With repeatable business processes in place, they could focus on operations. The result was that the founders could market and grow the company.

I then created a standard operating procedures guide for their production department.

Moving Forward

Having undertaken this project I was well suited to report on operational efficiencies, waste reduction and new business analytics.